Page 1 of 1

How to wire a DIN

Posted: Fri Mar 21, 2014 12:58 pm

by oakbarn

DIN wiring

Wiki:

Discrete Inputs are available for switches, push buttons, etc. They are also rated at +5VDC. To assert a Din, connect the Din terminal to the +5VDC terminal (presumably through a switch). To deassert the Din, simply disconnect the Din terminal, as there is a weak pulldown resistor that will pull the Din to ground.

The +5VDC pin is provided mainly for low current Din connections. However it can also be used to power external components, such as expansion cards or sensors, as long as they don't exceed the maximum current. The maximum current sourced from the +5VDC pin is 300mA.

Say I want a DIN1 switch to control (assert, deassert) an out.

I would wire the switch from the DIN1 5+v to one side of the switch. I would connect the other side of the switch to any of the GRNDS similar to hooking up the control side of an SSR?

Re: How to wire a DIN

Posted: Fri Mar 21, 2014 4:49 pm

by brewstarke

You got it. You can use that switch to start a process or change states, or if a float switch to control your fly sparges.

Endless possibilities.

Re: How to wire a DIN

Posted: Thu Oct 20, 2016 12:49 pm

by Cootkiller

Hello all first time poster here. I recently built a 1bbl stout tank setup all electric. I have brewed twice on this system and have found that I would like to use a float switch as an exit state for sparge control etc. How do I need to wire my switch so that when the switch is activated or deactivated I realize the transition on the BCS to use as an exit condition? I still would like to maintain the float safety feature for my elements. Can I have both?

Re: How to wire a DIN

Posted: Fri Oct 21, 2016 1:41 pm

by oakbarn

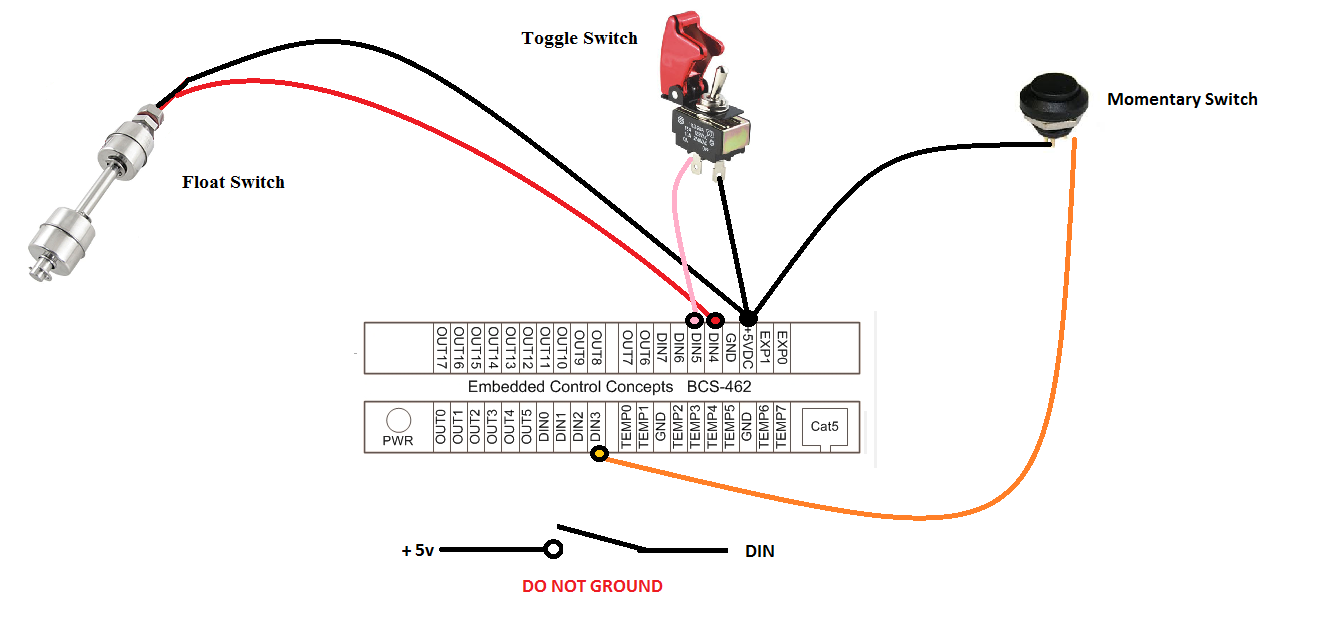

- Float Toggle.png (112.42 KiB) Viewed 15698 times

You simply wire the Float wires, one to the 5vdc and the Other to a DIN.

You set the Exit Condition to exit when the DIN is either "On" or "Off".

The ones I got from Amazon had two Floats and 2 red wires (top Float) and 2 Black wires (Bottom Float). The floats were "turned" so that they were "On" or "NC" when they are not floated. I could flip them to reverse but I found that I like the "NC" float better as it is made BEFORE it floats and I can see it Green on the Main Control Panel. When it Floats, it is "Off" or Open and the DIN Oval is Off on the Main Control Panel. I use these with a Valve to fill my Vessels with water and a 24 vdc 1/2 " Valve. The valve is turned on by a State in a Process and then turned Off and Exits the Fill State when the Float floats. The Exit Condition Allows you to select if the Float is "On" or "Off"

Although the Diagram shows a Red and Black wire to the Float, mine had 2 Reds!

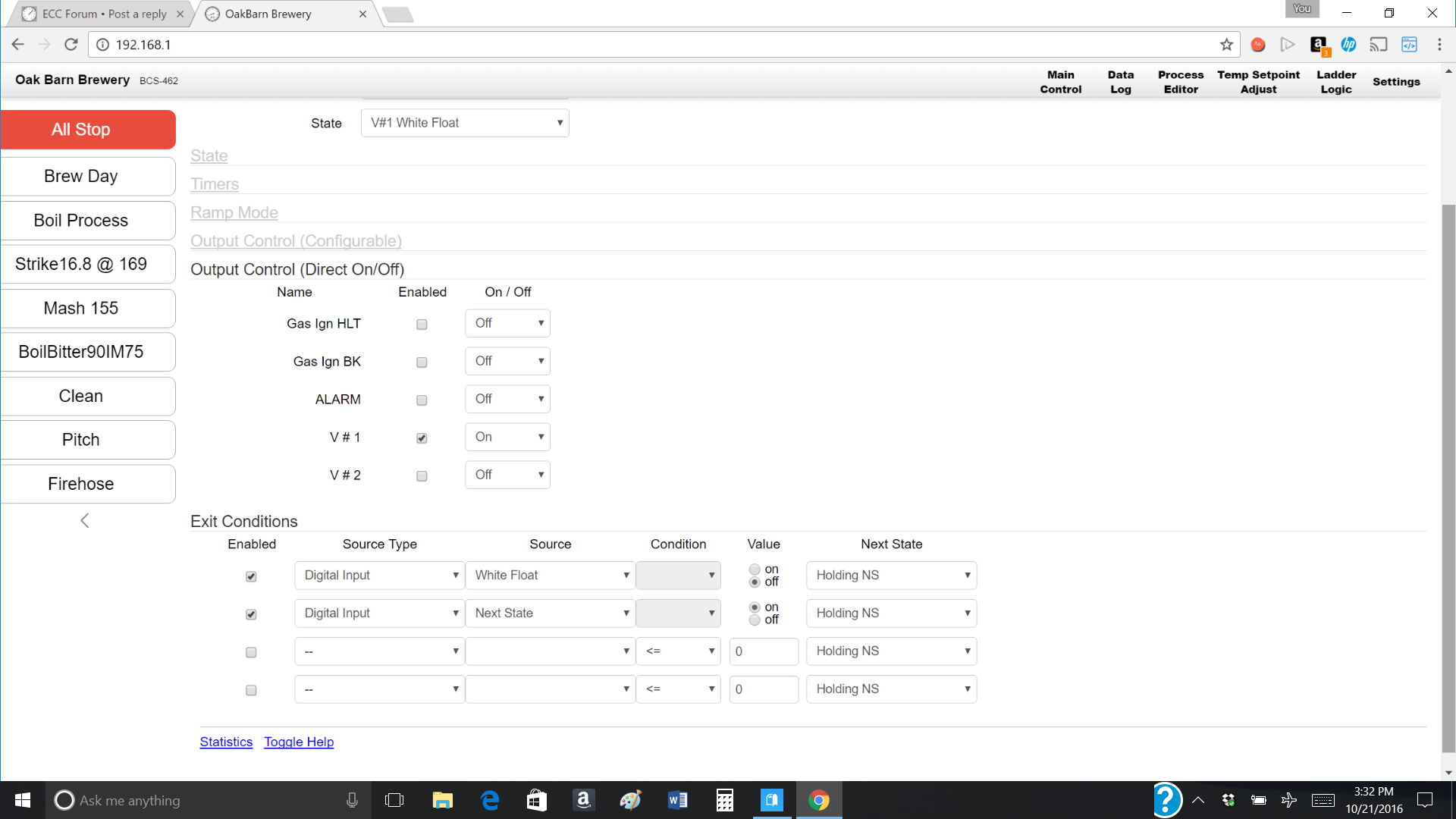

Here is a pix of my Process:

- exit.png (196.62 KiB) Viewed 15698 times

My State "V#1 White Float" (Named white because that is the color of the Wire attached to the DIN on the BCS. I also have a "Green Float")

When I go to this State, it Turns on my "V#1" valve.

I have two exits. One is the White Float and it exits to "Holding NS" State

Exit 2 uses my Next State DIN which is a Toggle Switch that I can turn "On" to close the V#1 valve as well.

Re: How to wire a DIN

Posted: Fri Oct 21, 2016 3:20 pm

by brewstarke

By 'float safety feature' I assume you're meaning to prevent an element from firing dry. I'd recommend putting a float switch in the SSR signal circuit so that SSR will only trigger when called to do so by the BCS AND the float is 'up' telling the system that you're element is not dry. I've inadvertently triggered outputs on my phone or tablet and having that hard wired solution minimizes risk/damages from situations like that.

Re: How to wire a DIN

Posted: Fri Oct 21, 2016 4:49 pm

by oakbarn

You can use Ladder Logic as well. This is a perfect case for it. The DIN (Float) can be "NC" or "NO" as you have it set up and the Element Out ON only made is the DIN is made.

You could also have 2 States where on has the Element "On" and Sparge Pump "Off". The Second State would have Element "Off" and Sparge Pump "On". Set Exit to each other. Are you trying to "Fly Sparge"?

Re: How to wire a DIN

Posted: Thu Nov 10, 2016 9:23 am

by losco70

Hi,

I would like to control a valve with a physical push button linked to a DIN that should assert/deassert an output overwriting any process.

Push first time -> out stay on

Push second time -> out stay off

How can I do it?

It is possible to do it even if no process is running?

Thank you

Luca

Re: How to wire a DIN

Posted: Thu Nov 10, 2016 9:37 am

by JonW

losco70 wrote:Hi,

I would like to control a valve with a physical push button linked to a DIN that should assert/deassert an output overwriting any process.

Push first time -> out stay on

Push second time -> out stay off

How can I do it?

It is possible to do it even if no process is running?

Thank you

Luca

Ladder logic is used to override processes exactly as you describe. The only difference is that you can't use a momentary switch, it would need to be an on/off style switch.

If you had a spare process, you could also program this logic into the process where pushing a momentary button once would turn on and pushing it again would turn off (by triggering states). You can also set a process to autostart and a higher number process overrides lower processes, so if this was programmed as process 7, it could override other processes.

The easiest solution though is to do as you originally wanted and just use an on/off button instead of a momentary button.

Re: How to wire a DIN

Posted: Thu Nov 10, 2016 9:47 am

by losco70

JonW wrote:

Ladder logic is used to override processes exactly as you describe. The only difference is that you can't use a momentary switch, it would need to be an on/off style switch.

If you had a spare process, you could also program this logic into the process where pushing a momentary button once would turn on and pushing it again would turn off (by triggering states). You can also set a process to autostart and a higher number process overrides lower processes, so if this was programmed as process 7, it could override other processes.

The easiest solution though is to do as you originally wanted and just use an on/off button instead of a momentary button.

I was thinking to a push button because I have already some button wired and not used in my panel, but as I have to change them I think that I will use a 3 way selector (manual_open/manual_close/bcs_auto)

Thank you

Luca