I'm using gas for my Boil kettle and while brewing with a friend he complained that took to long for us to go from mash out to full boil. I brew in my basement so I don't want a huge burner cycling on and off.

I jetted my first burner to give a nice rolling boil and never shut off.

Yesterday, I installed a two ring burner and can go from 167 to full boil in 24 minutes. I then shut off the outer ring and maintain the boil and not shut the inner burner off.

I was thinking of using ladder logic to control the solenoid valve for the outer ring, but am unsure on how to do it.

The process would work like this. The temp probe will control the gas valve and solenoid valve. I want the solenoid valve to cycle shut off at 210.5 F and on at anything lower. This should prevent a boil over. I don't see in the ladder logic any codes that are for temp control, is this not possible.

Thanks Todd

Two stage gas burner

-

JonW

- Site Admin

- Posts: 1726

- Joined: Sun Jul 18, 2010 7:51 am

- Bot?: No

- Location: Huntington Beach, CA

- Contact:

Re: Two stage gas burner

You could do it with 2 states within your boil process. Call them something like "Boil High" and "Boil Low". Using conditional logic, you could jump between the two states to control the use of the outer ring.

Re: Two stage gas burner

Jon,

That could be an option. I'm used to furnaces that do that with two stage gas valves but they need to run at low fire for 10 min before going to high fire.

I would want to have the conditional logic of say, more than 10 F below target temp then high fire.

I have a couple of thoughts on why I want the two stages. One is to bring up to boil quickly and then low fire so that I don't boil off too much wort.

and the second is when I build my 1.5 bbl system it uses the same set up.

That could be an option. I'm used to furnaces that do that with two stage gas valves but they need to run at low fire for 10 min before going to high fire.

I would want to have the conditional logic of say, more than 10 F below target temp then high fire.

I have a couple of thoughts on why I want the two stages. One is to bring up to boil quickly and then low fire so that I don't boil off too much wort.

and the second is when I build my 1.5 bbl system it uses the same set up.

-

JonW

- Site Admin

- Posts: 1726

- Joined: Sun Jul 18, 2010 7:51 am

- Bot?: No

- Location: Huntington Beach, CA

- Contact:

Re: Two stage gas burner

I've thought about doing this with my direct fired mash tun. I was thinking of having two different solenoid valves (and manual adjustment valves) feeding my single burner so I could activate one valve to put the burner on full for heating strike water and then only activate the second solenoid during mash recirc so that it was slowly heated. I sometimes forget to turn the burner down after heating strike water and then it spikes the mash temp when the mash starts recirculating.

Re: Two stage gas burner

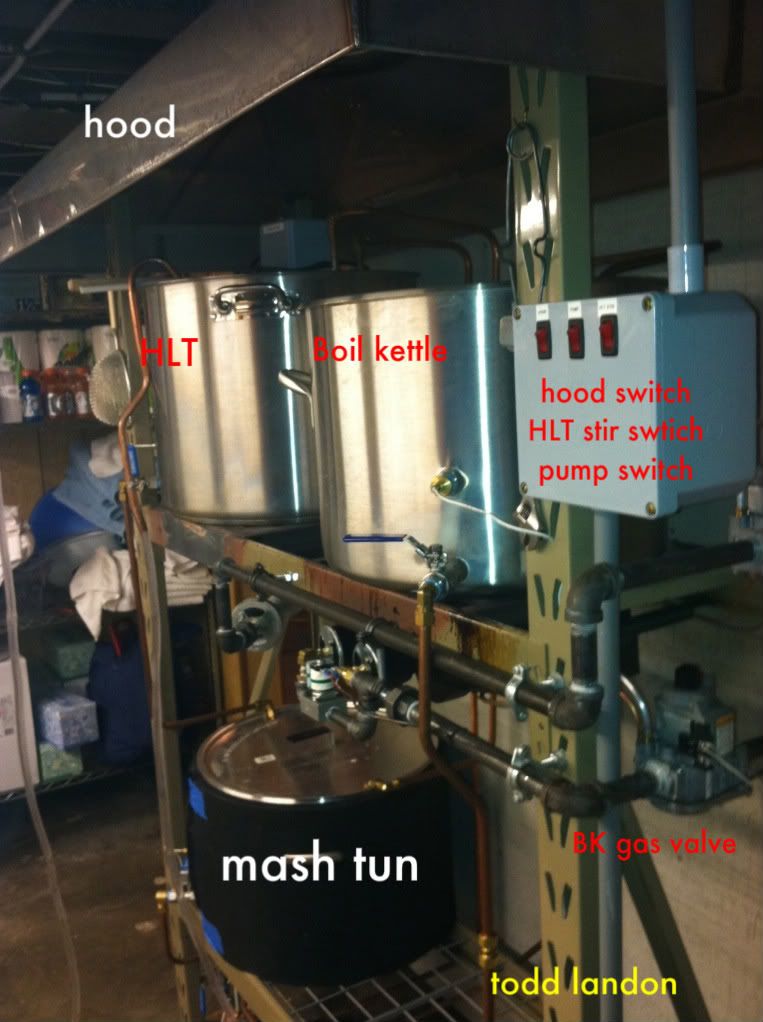

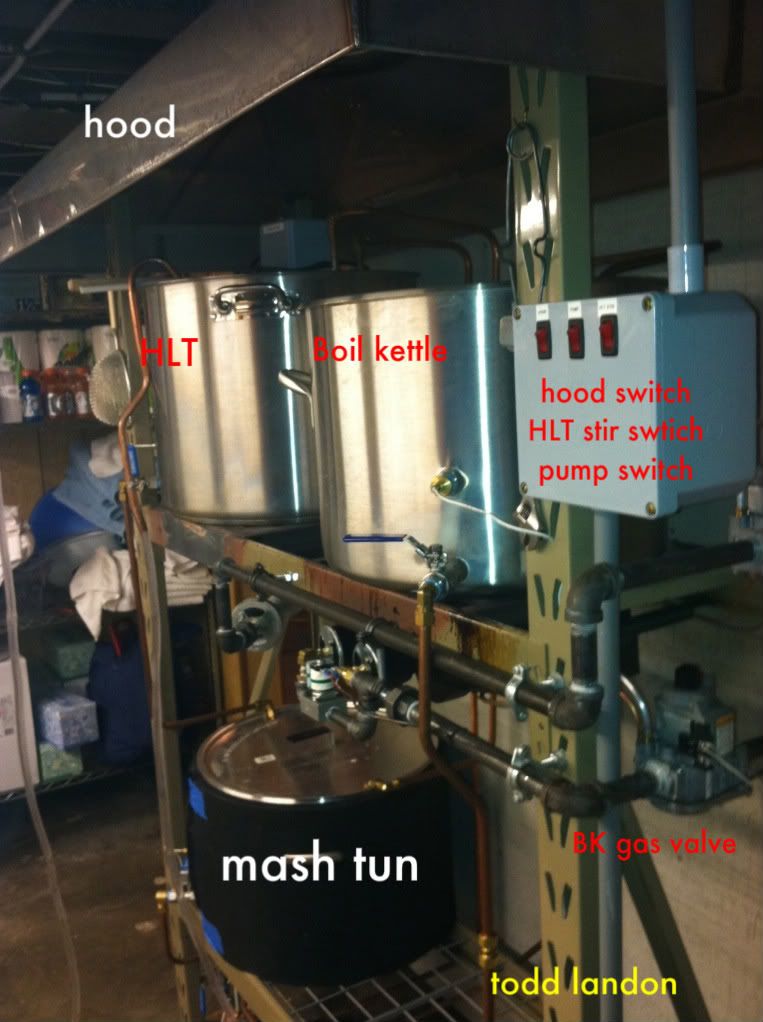

Great idea. Nice stand, btw.

I think to get the behavior that your looking for, a simple one state process (or manual mode) will work? Just to make sure that I have this straight, you want the inner burner to remain on all of the time, and the outer burner to turn on/off at 210.5

ProcessX Boil

State0: Dual Burner Boil

Output Inner Heat = Direct On

Output Outer Heat = Hysteresis Controlled, setpoint 210.5. (Set the hyst range to 0 in System Settings)

I think to get the behavior that your looking for, a simple one state process (or manual mode) will work? Just to make sure that I have this straight, you want the inner burner to remain on all of the time, and the outer burner to turn on/off at 210.5

ProcessX Boil

State0: Dual Burner Boil

Output Inner Heat = Direct On

Output Outer Heat = Hysteresis Controlled, setpoint 210.5. (Set the hyst range to 0 in System Settings)

Re: Two stage gas burner

you can see the burner and the inner two rings are seperate from the outer. I could have only the outer on but would need to move the pilot assy.

I could put another switch with the pump, stirrer, and hood switches in this box which I have plenty of room but I really want it to be automatic. More so for my next 1.5 BBl system.

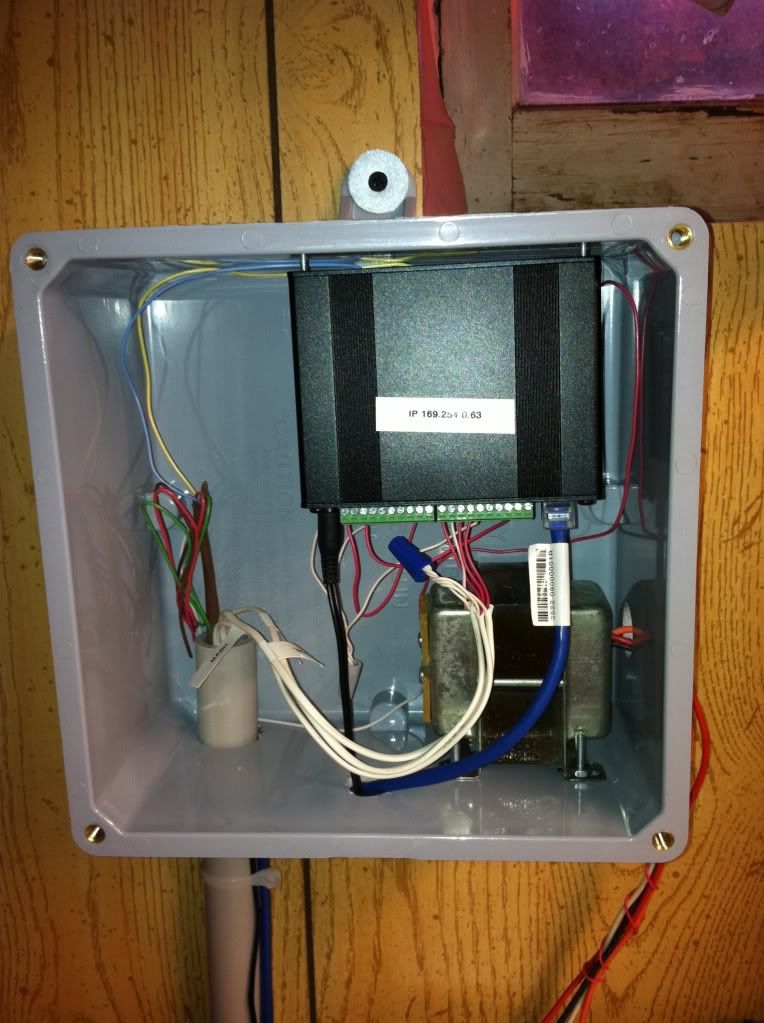

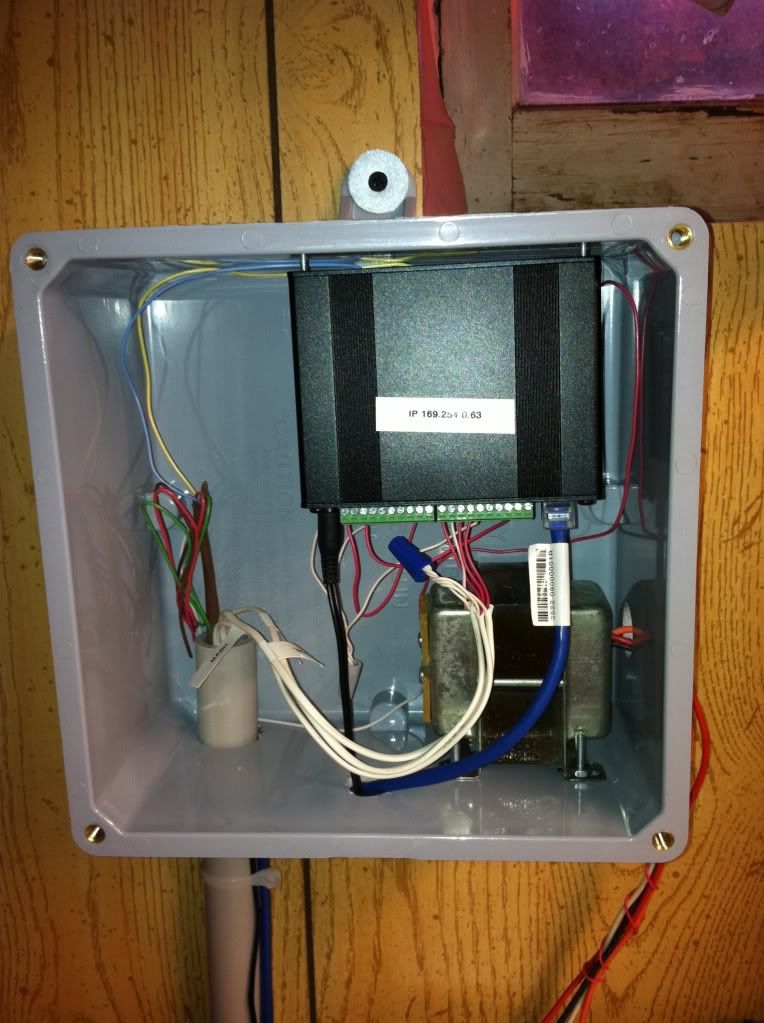

I have the ssrs and bcs and transformer over in my low voltage box ( the ssrs are behind the bcs)

so i want to have this really be a process, but i don't really know how to program it yet.

thanks for the compliment on the brew stand. todd

I could put another switch with the pump, stirrer, and hood switches in this box which I have plenty of room but I really want it to be automatic. More so for my next 1.5 BBl system.

I have the ssrs and bcs and transformer over in my low voltage box ( the ssrs are behind the bcs)

so i want to have this really be a process, but i don't really know how to program it yet.

thanks for the compliment on the brew stand. todd

Re: Two stage gas burner

Trying to automate getting up to boil quickly, then reducing the heat input to prevent boil overs is extremely tricky. Not even the electric fired PID controlled boys, where overshoot can be compensated for dynamically, advocate trying this. It is tricky enough stepping away from a "dialed in" boil. If the hot break starts making an insulating foam layer, it triggers an imminent boil over situation.

I assume water boils at ~212F where you are, hence the -1.5F shutoff at 210.5F is to prevent overshoot. After a few runs you might be able to get a feel for how much below boiling to set the shutoff, but it will be tricky. There will always be some variance in the behavior. Also, that last bit of high heat before boil seems like it is very critical, and if the set point is low by just a bit, it may never reach boil with the reduced output.

Placing some needle valves prior to the burner orifices will make fine tuning and adjustments a lot easier than swapping orifices, especially mid-boil. Maybe you already have some, and I just couldn't see them in the pics.

1.5 BBL direct fired BK? Is that actual size, or batch size? I have seen guys use ~50g pots, but those have a ~1BBL batch size. A 1.5BBL batch size would require at least a 2BBL capacity BK. Even the 50 gallon pots are pushing the practical limits of direct firing. I think this is the reason you don't see many pots, especially stainless, above ~25 gallon. Most restaurant gear above ~15 gallons is steam jacketed.

I assume water boils at ~212F where you are, hence the -1.5F shutoff at 210.5F is to prevent overshoot. After a few runs you might be able to get a feel for how much below boiling to set the shutoff, but it will be tricky. There will always be some variance in the behavior. Also, that last bit of high heat before boil seems like it is very critical, and if the set point is low by just a bit, it may never reach boil with the reduced output.

Placing some needle valves prior to the burner orifices will make fine tuning and adjustments a lot easier than swapping orifices, especially mid-boil. Maybe you already have some, and I just couldn't see them in the pics.

1.5 BBL direct fired BK? Is that actual size, or batch size? I have seen guys use ~50g pots, but those have a ~1BBL batch size. A 1.5BBL batch size would require at least a 2BBL capacity BK. Even the 50 gallon pots are pushing the practical limits of direct firing. I think this is the reason you don't see many pots, especially stainless, above ~25 gallon. Most restaurant gear above ~15 gallons is steam jacketed.

Re: Two stage gas burner

KnowItAll,

The inner two rings will bring the pot to boil without a boil over, it just will take longer. You are correct that I may or may not boil at 212F and what my idea of a boil is different than yours.

Gas is a different animal than electricity, once it's off it's off and no btu transfer.

No needle valves just one setting for every boil.

Can you explain why 50 gals is the practical limit of direct fire, please. Todd

The inner two rings will bring the pot to boil without a boil over, it just will take longer. You are correct that I may or may not boil at 212F and what my idea of a boil is different than yours.

Gas is a different animal than electricity, once it's off it's off and no btu transfer.

No needle valves just one setting for every boil.

Can you explain why 50 gals is the practical limit of direct fire, please. Todd

-

clearwaterbrewer

- Posts: 383

- Joined: Wed Feb 09, 2011 3:43 pm

- Bot?: No

- Location: Clearwater, FL

- Contact:

Re: Two stage gas burner

I will throw out two nit-picks...

Electric as in what we are using (immersed elements with very small heat capacity) is very similar to gas when you shut it off, the boil stops within a second.. It may actually be faster going off-boil than gas on some boil pots, especially if compared to Keggles that have a large amount of metal that is hotter than the wort when you shut off the burner... there is more metal touching flame than there is in a water heater element...

Direct fired gas can heat a 7BBL system, but by that size, it has to be 'jacketed'. My local Belgian style brewery has used one since it's inception. http://www.saintsomewherebrewing.com/

I stopped having boilovers when recirculating for the entire mash.... the wort is crystal clear...

-mike

Electric as in what we are using (immersed elements with very small heat capacity) is very similar to gas when you shut it off, the boil stops within a second.. It may actually be faster going off-boil than gas on some boil pots, especially if compared to Keggles that have a large amount of metal that is hotter than the wort when you shut off the burner... there is more metal touching flame than there is in a water heater element...

Direct fired gas can heat a 7BBL system, but by that size, it has to be 'jacketed'. My local Belgian style brewery has used one since it's inception. http://www.saintsomewherebrewing.com/

I stopped having boilovers when recirculating for the entire mash.... the wort is crystal clear...

-mike